In 1986, James Richmond sacrificed his beloved 1966 Pontiac LeMans in order to put a down payment on a 108” Hanchett grinder. Since then, what originally began as a one-man operation in Richmond’s garage has blossomed into a highly successful enterprise. Over the years, Midwest Knife Grinding, Inc. has expanded their offerings to include metal shear blades, underwater pelletizer knives, pelletizer rotor heads, granulator knives, pulverizer discs and segments, and various other recycling knives. In addition to working with a number of companies in the state of Ohio, Midwest Knife Grinding, Inc. has also earned a reputation among U.S. businesses throughout the greater Atlanta, Georgia area as well as Pennsylvania, Virginia, Texas, California, and beyond. Needless to say, their experience working with machine knives makes Midwest Knife Grinding, Inc. uniquely qualified to provide your own business with the parts you need to keep your equipment running smoothly.

In 1986, James Richmond sacrificed his beloved 1966 Pontiac LeMans in order to put a down payment on a 108” Hanchett grinder. Since then, what originally began as a one-man operation in Richmond’s garage has blossomed into a highly successful enterprise. Over the years, Midwest Knife Grinding, Inc. has expanded their offerings to include metal shear blades, underwater pelletizer knives, pelletizer rotor heads, granulator knives, pulverizer discs and segments, and various other recycling knives. In addition to working with a number of companies in the state of Ohio, Midwest Knife Grinding, Inc. has also earned a reputation among U.S. businesses throughout the greater Atlanta, Georgia area as well as Pennsylvania, Virginia, Texas, California, and beyond. Needless to say, their experience working with machine knives makes Midwest Knife Grinding, Inc. uniquely qualified to provide your own business with the parts you need to keep your equipment running smoothly.

Unlike other companies that offer such manufacturing and resharpening services, Midwest Knife Grinding, Inc. wasn’t created on a whim. Instead, it was built on years of experience in the field. Following various vocational courses in metal working and machine shop that he took while attending high school, owner James Richmond continued his education at Glen Oaks Community College, Kent State University, and the Akron Machining Institute. After running the tool cutter department at North American Products for over a decade, Richmond decided to start his own company in order to branch out and provide himself with a greater challenge. The end result? An Ohio-based business that is frequently contacted by companies throughout the United States, including those in Atlanta, Pennsylvania, Virginia, Texas, and California. They’ve even worked with international clients as far away as Belgium.

Unlike other companies that offer such manufacturing and resharpening services, Midwest Knife Grinding, Inc. wasn’t created on a whim. Instead, it was built on years of experience in the field. Following various vocational courses in metal working and machine shop that he took while attending high school, owner James Richmond continued his education at Glen Oaks Community College, Kent State University, and the Akron Machining Institute. After running the tool cutter department at North American Products for over a decade, Richmond decided to start his own company in order to branch out and provide himself with a greater challenge. The end result? An Ohio-based business that is frequently contacted by companies throughout the United States, including those in Atlanta, Pennsylvania, Virginia, Texas, and California. They’ve even worked with international clients as far away as Belgium.

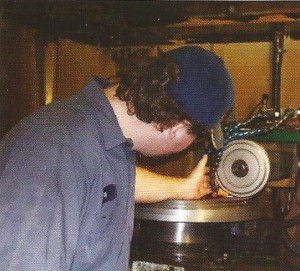

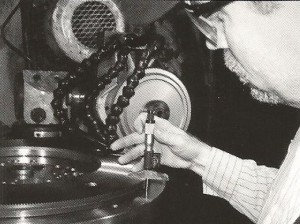

What sets Midwest Knife Grinding, Inc. apart from the competition is the fact that they have over twenty skilled employees as well as some of the best grinding equipment in the country, yet they’re still able to give clients the individual attention they deserve. Whether you’re in the market for pelletizer rotor heads, underwater pelletizer knives, metal shear blades, granulator blades, refiner plates, or any other recycling knives, you can feel confident that Midwest Knife Grinding’s team will process your order in a timely manner. Plus, you can look forward to receiving only high-quality work in terms of new and resharpened machine knives as some of the machines in their shop are identical to those used in the initial manufacturing process. Not only does this ensure accuracy, but quick turnaround rates as well.

What sets Midwest Knife Grinding, Inc. apart from the competition is the fact that they have over twenty skilled employees as well as some of the best grinding equipment in the country, yet they’re still able to give clients the individual attention they deserve. Whether you’re in the market for pelletizer rotor heads, underwater pelletizer knives, metal shear blades, granulator blades, refiner plates, or any other recycling knives, you can feel confident that Midwest Knife Grinding’s team will process your order in a timely manner. Plus, you can look forward to receiving only high-quality work in terms of new and resharpened machine knives as some of the machines in their shop are identical to those used in the initial manufacturing process. Not only does this ensure accuracy, but quick turnaround rates as well.

This Ohio-based company is constantly adding new equipment to their shop in order to better serve their clients. With over 45 pieces of equipment available, including grinding machines, milling machines, lathes, machining centers, and more, Midwest Knife Grinding, Inc. is more than capable of performing the work you require. To learn more about the services they offer for pelletizer rotor heads, underwater pelletizer knives, metal shear blades, granulator blades, pulverizer discs and segments, and other recycling knives, visit their website at www.midwestknife.com. If you have additional questions about resharpening the machine knives used at your facility, feel free to give Midwest Knife Grinding, Inc. a call at 330.854.1030 to speak with a knowledgeable staff member. You’ll quickly see why companies throughout the Atlanta, Georgia area as well as those as far as Pennsylvania, Virginia, Texas, and even California choose Midwest Knife Grinding, Inc. for all of their resharpening and manufacturing needs.

This Ohio-based company is constantly adding new equipment to their shop in order to better serve their clients. With over 45 pieces of equipment available, including grinding machines, milling machines, lathes, machining centers, and more, Midwest Knife Grinding, Inc. is more than capable of performing the work you require. To learn more about the services they offer for pelletizer rotor heads, underwater pelletizer knives, metal shear blades, granulator blades, pulverizer discs and segments, and other recycling knives, visit their website at www.midwestknife.com. If you have additional questions about resharpening the machine knives used at your facility, feel free to give Midwest Knife Grinding, Inc. a call at 330.854.1030 to speak with a knowledgeable staff member. You’ll quickly see why companies throughout the Atlanta, Georgia area as well as those as far as Pennsylvania, Virginia, Texas, and even California choose Midwest Knife Grinding, Inc. for all of their resharpening and manufacturing needs.

Midwest Knife Grinding, Inc.

Ph: 330.854.1030

www.midwestknife.com