By Gemma Chriss

Companies that specialize in compounding and manufacturing know that machine knives need to be kept sharp for optimum performance. Unfortunately, blade grinding is task that requires specialized equipment not often found in the average facility, especially in the case of helical rotors and pelletizer rotors. Though many companies throughout Texas, Louisiana, Mississippi, and beyond are wary of obtaining outside help, Midwest Knife Grinding, Inc. has proven to be a reliable source for pelletizer rotor and helical rotor sharpening services. This Ohio-based business possesses a highly trained staff and a number of advanced machines capable of revitalizing dull pelletizer rotors and helical rotors, ensuring that their clients receive the parts they need for their equipment.

Companies that specialize in compounding and manufacturing know that machine knives need to be kept sharp for optimum performance. Unfortunately, blade grinding is task that requires specialized equipment not often found in the average facility, especially in the case of helical rotors and pelletizer rotors. Though many companies throughout Texas, Louisiana, Mississippi, and beyond are wary of obtaining outside help, Midwest Knife Grinding, Inc. has proven to be a reliable source for pelletizer rotor and helical rotor sharpening services. This Ohio-based business possesses a highly trained staff and a number of advanced machines capable of revitalizing dull pelletizer rotors and helical rotors, ensuring that their clients receive the parts they need for their equipment.

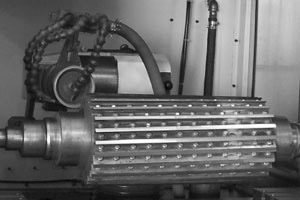

To ensure that pelletizer rotor and/or helical rotor sharpening is done correctly, the machinists at Midwest Knife Grinding, Inc. follow the same proven procedures every time. When pelletizer rotors and helical rotors come into the shop, they undergo a thorough visual inspection to determine if any flaws are present. For helical rotors, the technicians check to see if there’s damage on the bearing journals as well as the teeth. For pelletizer rotors, they check to see if there’s damage on the individual blades.

To ensure that pelletizer rotor and/or helical rotor sharpening is done correctly, the machinists at Midwest Knife Grinding, Inc. follow the same proven procedures every time. When pelletizer rotors and helical rotors come into the shop, they undergo a thorough visual inspection to determine if any flaws are present. For helical rotors, the technicians check to see if there’s damage on the bearing journals as well as the teeth. For pelletizer rotors, they check to see if there’s damage on the individual blades.

Once approved by the customer, the machinists perform any necessary repairs. They then move on to blade grinding. During pelletizer rotor and helical rotor sharpening, the parts are ground on multi-axis CNC machines. This Ohio-based business is currently capable of grinding up to a 29” flute length and a 14” diameter. However, they will soon possess another piece of equipment that can grind up to a 39” flute length and a 14” diameter. Unlike other businesses that re-sharpen machine knives, Midwest Knife Grinding, Inc. has the required equipment and is also able to accommodate significantly larger pelletizer rotors and helical rotors.

In order for the rotors to maintain their proper temper and material quality, the machinists at Midwest Knife Grinding use a high-pressure flood coolant system during the blade grinding process. The inside flute as well as the primary and secondary angles on the outside diameter of the cutter are ground to ensure minimal removal during each sharpening. This step is worth noting, as clients can look forward to increased savings throughout the life of their helical or pelletizer rotor. Clients can also feel confident that Midwest Knife Grinding’s machinists grind each tooth to its exact geometric profile and kept in index.

In order for the rotors to maintain their proper temper and material quality, the machinists at Midwest Knife Grinding use a high-pressure flood coolant system during the blade grinding process. The inside flute as well as the primary and secondary angles on the outside diameter of the cutter are ground to ensure minimal removal during each sharpening. This step is worth noting, as clients can look forward to increased savings throughout the life of their helical or pelletizer rotor. Clients can also feel confident that Midwest Knife Grinding’s machinists grind each tooth to its exact geometric profile and kept in index.

After a final inspection for quality assurance purposes, the rotor is packed for shipping and returned to the client in a timely manner, regardless of whether they’re located in Texas, Louisiana, Mississippi or beyond. Despite the fact that Midwest Knife Grinding’s team follows the same multi-step procedures for each order, they strive to complete every job as quickly as possible without sacrificing quality.

Those in need of repaired pelletizer rotors and/or helical rotors are encouraged to visit Midwest Knife Grinding’s website at www.midwestknifegrinding.com. There they can learn more about the blade grinding services this Ohio-based company provides to clients. Additional questions about pelletizer rotor and helical rotor sharpening can also be addressed by contacting Midwest Knife Grinding, Inc. directly at 330.854.1030. Their friendly and knowledgeable staff members are always happy to offer quotes to businesses in Texas, Louisiana, Mississippi, and beyond that require sharpening services for their machine knife equipment.

Midwest Knife Grinding, Inc.

Ph: 330.854.1030

www.midwestknifegrinding.com